- #Inductive automation ignition get data from website serial

- #Inductive automation ignition get data from website software

- #Inductive automation ignition get data from website code

#Inductive automation ignition get data from website software

The hardware and software design achieved DNV-GL Plan approval using readily available industrial-standard hardware and software. The project was completed within the specified time frame. The outcome for Incat and Cromarty was extremely positive. The Ignition operator interface graphics were designed in collaboration with Incat and planned to be deployed around the vessel to offer a simplified graphical representation so that any abnormal or urgent situations could be quickly highlighted to the operators.Īfter development and before deployment, the system was thoroughly bench-tested not only to provide comprehensive factory testing assurances but also being successfully assessed by a DNV representative to achieve DNV-GL accreditation.

#Inductive automation ignition get data from website code

The M580 platform offers an open, flexible, robust, and powerful system supporting high levels of complex applications, and allowed the design and engineering of the PLC code architecture to be scalable and modularized to meet current and potential future vessel requirements.įor local operator interfaces, Winmate rugged Marine Panel PCs were selected.

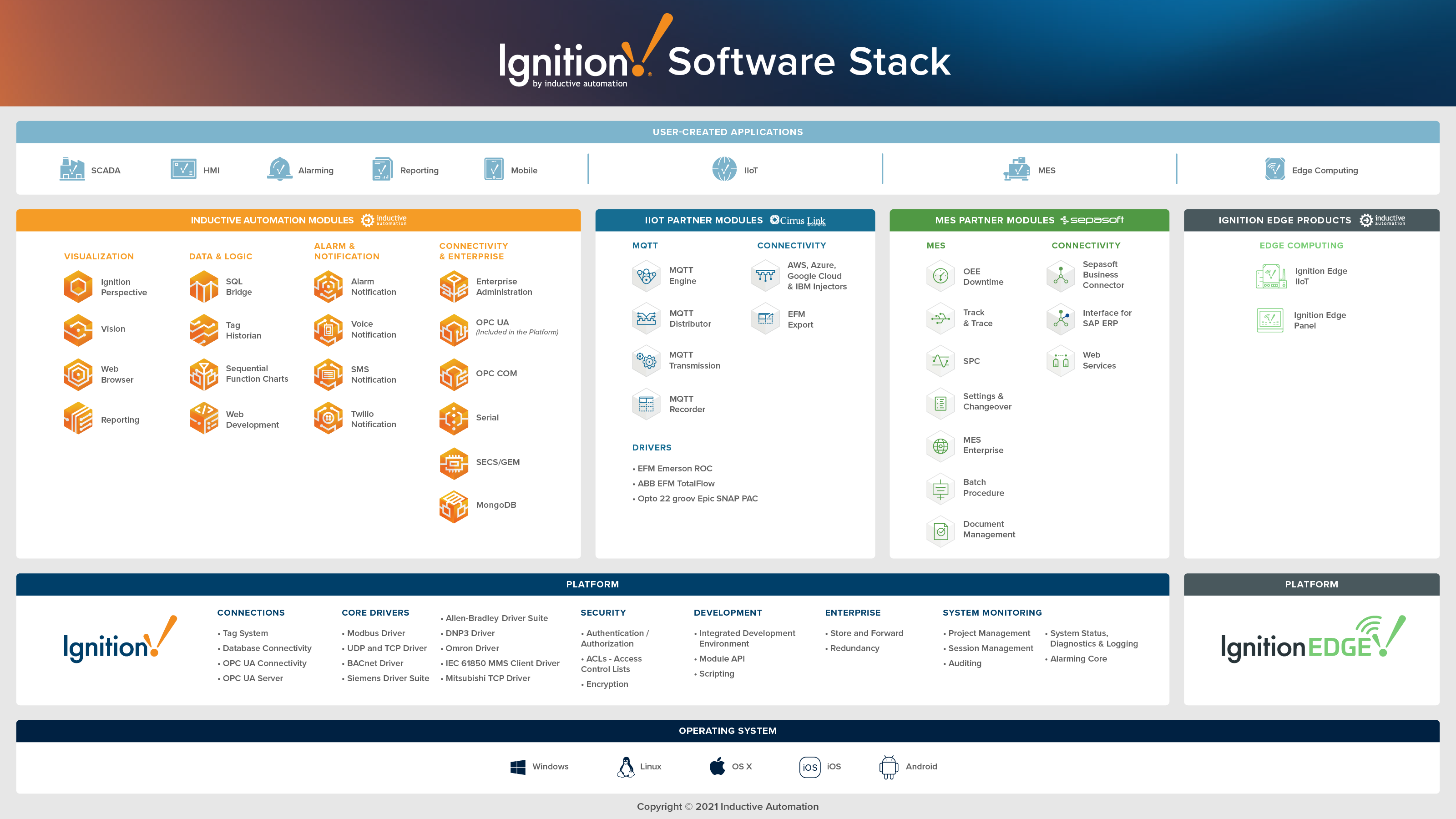

The PLC platform selected was a Schneider Electric Modicon M580 PLC engineered in a hot standby arrangement with Modicon X80 Ethernet RIO modules connected via a redundant Ethernet Ring. Combined with instant web-based deployment, alarming, reporting, and redundant servers all on one open and scalable universal, versatile platform made Ignition an ideal fit for the application. Therefore, there is no need to purchase additional licensing should the number of tags or clients increase. It is supplied with an unlimited licensing model meaning unlimited tags, clients, screens, and connections. Ignition was selected because it is a highly versatile solution built upon trusted industry standards. The SCADA platform chosen was an Inductive Automation Ignition SCADA arranged in a redundant server configuration. To meet this requirement, Cromarty carefully selected proven industrial solutions. Cromarty’s main design consideration was to provide a scalable solution that could be applied to this and subsequent vessels while ensuring high availability. The SIMS also needed to be fit for marine applications, achieving DNV-GL approval in accordance with DNV GL rules for high-speed and light craft.Ĭromarty was awarded the contract to develop a SIMS for Vessel 091, a 111-meter wave-piercing catamaran. The touchscreens need to provide a common operator interface no matter where on the vessel the operator was located and must have the ability to be expanded as required. The data and control needed to be distributed to touchscreen operator workstations throughout the vessel.

#Inductive automation ignition get data from website serial

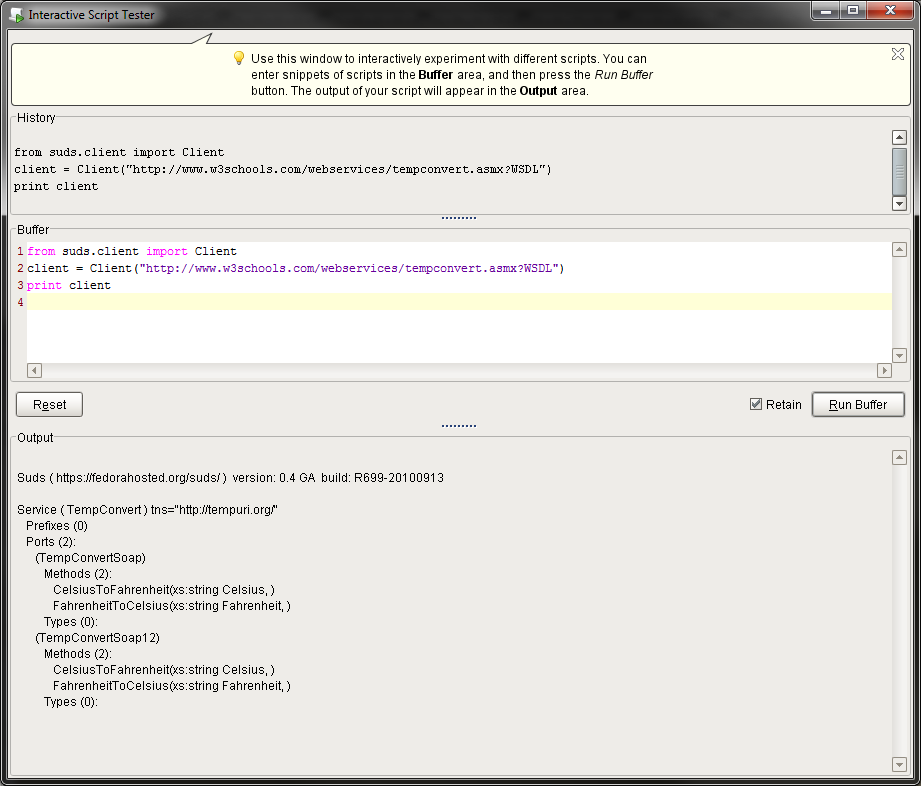

The SIMS needs to manage analog and digital data from a variety of ship’s plant equipment through hardwired signal inputs, switched relay outputs, and serial interfaces. To assist in the development, Incat identified the need for a partner with wide-ranging electrical and automation skills and, importantly, had a local presence to Incat’s operations so the two companies could closely work together to develop a SIMS suitable for use on this vessel - and flexible enough to be implemented on Incat’s upcoming vessels. Incat decided that to get a system that would meet the specific needs of the vessel they would need to develop one themselves. The purpose of the SIMS is to manage data from various inputs and present data in a consistent manner on operator workstations distributed throughout a vessel.ĭue to the unique nature of the vessel design, a bespoke SIMS was required. Ships vary from fast, flexible, and efficient vehicle-passenger ferries to high-speed military support vessels, crew ships, and dynamic platforms.Įach Incat ship requires a Ship Integrated Management System (SIMS).

The purpose of the project was to develop a DNV-GL approved Ship Integrated Management System (SIMS) to manage data from various inputs on the ship and present information in a consistent manner on operator workstations distributed throughout the vessel.Īustralian shipbuilder Incat, based in Hobart, Tasmania, designs and builds high-speed lightweight catamarans which are supplied globally. Improved Data Management for High-Speed Catamarans

0 kommentar(er)

0 kommentar(er)